|

||||||||||||

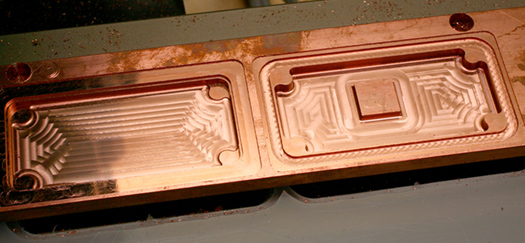

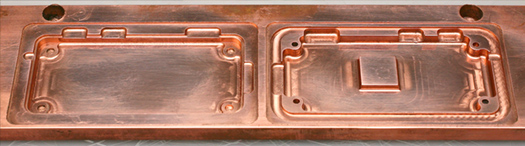

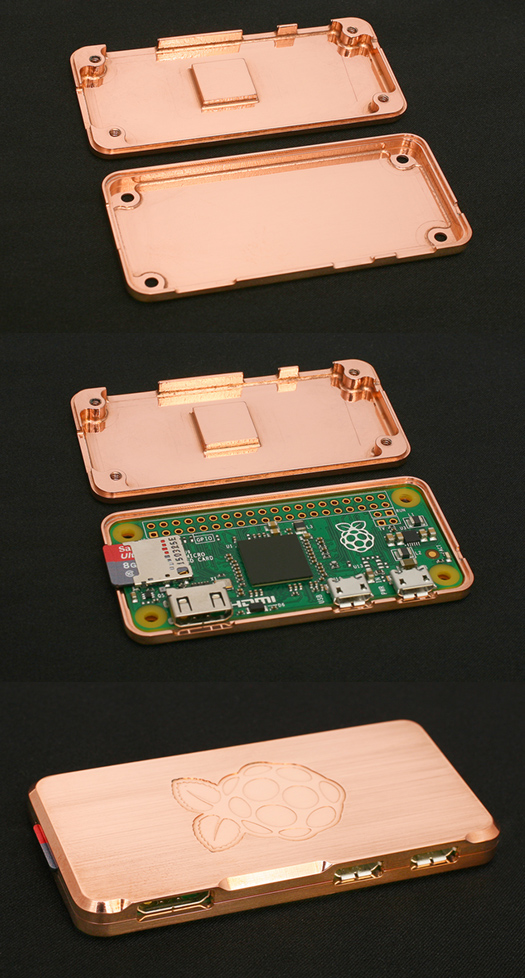

| So I was fortunate enough to pick up one of the first Raspberry Pi Zeros before they went out of stock. I thought the idea of a $5 computer was so cool I wanted to make a case worthy of that idea. I thought about the design here and there for a few months before deciding last week to get off the dime already! I wanted to make a case from metal, and even if it doesn't really need it, I thought I could have a pad on the top touch the processor (with a little heat paste) to turn the case into a big heatsink. Few metals beat copper when it comes to conducting heat, and copper has such a nice warm color, so copper it was. Here's how it came together (click photos for higher res versions): |

||||||||||||

|

||||||||||||